Speed Governor

Advantage

Applied under precise flow control precision motion control

Compact design at flow rates comparable to large-scale joint range

All models have the outlet and inlet adjustment adjustment both designs

PT tooth or tooth NPT has drop-resistant treatment

Application

Pneumatic linear motor speed control valve

The main means for moving the machine in such cylinders, pneumatic linear motor

Fluid / Air ( Not available for other gases or liquids )

Working pressure / 0 ~ 150 PSI / 0 ~ 9.9 Kgf / cm2( 0 ~ 990 KPa )

Negative / -29.5 in Hg / -750 mmHg ( -750 Torr )

Operating temperature range / 32 ~ 140 ℉ / 0 ~ 60 ℃

An intake adjustment and two types of outlet adjustment

Place An Order

Proposed order or inquiry

Please indicate food items:

Please specify the following items:

1. Model 2. Diameter 3. Teeth specifications

Size code teeth

01 : 1 / 8 ” / N 01 : 1 / 8 ” NPT / G 01 : 1 / 8 ” BSPP

02 : 1 / 4 ” / N 02 : 1 / 4 ” NPT / G 02 : 1 / 4 ” BSPP

03 : 3 / 8 ” / N 03 : 3 / 8 ” NPT / G 03 : 3 / 8 ” BSPP

04 : 1 / 2 ” / N 04 : 1 / 2 ” NPT / G 04 : 1 / 2 ” BSPP

Examples inquiry

SC-type governor

8 mm Diameter 1 / 4 ” PT tooth

| Model | Diameter | Teeth specifications |

|---|---|---|

| SC | 08 | 02 |

1 / 4 ” Diameter 1 / 4 ” PT tooth

| Model | Diameter | Teeth specifications |

|---|---|---|

| SC | 1 / 4 | 02 N |

8 mm Diameter 1 / 4 ” BSPP tooth

| Model | Diameter | Teeth specifications |

|---|---|---|

| SC | 08 | G 02 |

Metric fittings

Outlet adjustment ( Blue pressure ring ), the intake adjustment ( Red compression ring )

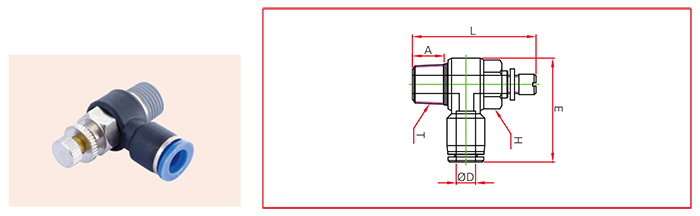

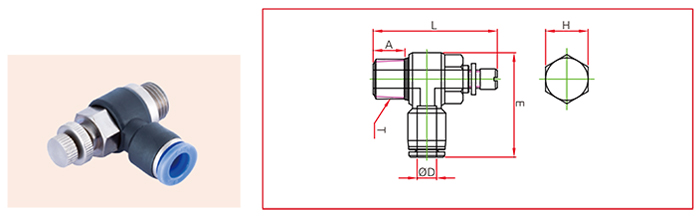

SC curved activity rotary

| Model | Ø D | T ( Thread ) |

E | L MIN |

L MAX |

A | B | H | Ø P |

|---|---|---|---|---|---|---|---|---|---|

| SC 04 - M 5 | 4 | M 5 x P 0.8 | 24.5 | 35 | 38.5 | 3.5 | 15 | 8 | 11 |

| SC 04 - 01 | 4 | PT 1 / 8 | 29.5 | 36 | 41 | 7.5 | 14 | 12 | 12.5 |

| SC 04 - 02 | 4 | PT 1 / 4 | 33 | 43 | 48.5 | 11.4 | 14 | 14 | 13 |

| SC 06 - M 5 | 4 | M 5 x P 0.8 | 26.5 | 35 | 38.5 | 3.5 | 15 | 8 | 13 |

| SC 06 - 01 | 6 | PT 1 / 8 | 30 | 36 | 41 | 7.5 | 14 | 12 | 13 |

| SC 06 - 02 | 6 | PT 1 / 4 | 34 | 43 | 48.5 | 11.4 | 14 | 14 | 13 |

| SC 06 - 03 | 6 | PT 3 / 8 | 39.5 | 48.5 | 54 | 12.8 | 14 | 19 | 13 |

| SC 08 - 01 | 8 | PT 1 / 8 | 32.5 | 36 | 41 | 7.5 | 17 | 12 | 14.5 |

| SC 08 - 02 | 8 | PT 1 / 4 | 37.5 | 43 | 48.5 | 11.4 | 17 | 14 | 14.5 |

| SC 08 - 03 | 8 | PT 3 / 8 | 40 | 48.5 | 54 | 12.8 | 17 | 19 | 14.5 |

| SC 08 - 04 | 8 | PT 1 / 2 | 46 | 56 | 61.5 | 15.5 | 17 | 24 | 14.5 |

| SC 10 - 01 | 10 | PT 1 / 8 | 37 | 36 | 41 | 7.5 | 21 | 12 | 18.5 |

| SC 10 - 02 | 10 | PT 1 / 4 | 41 | 43 | 48.5 | 11.4 | 21 | 14 | 18.5 |

| SC 10 - 03 | 10 | PT 3 / 8 | 44 | 48.5 | 54 | 12.8 | 21 | 19 | 18.5 |

| SC 10 - 04 | 10 | PT 1 / 2 | 49.5 | 56 | 61.5 | 15.5 | 21 | 24 | 18.5 |

| SC 12 - 02 | 12 | PT 1 / 4 | 42.5 | 43 | 48.5 | 11.4 | 21 | 14 | 21 |

| SC 12 - 03 | 12 | PT 3 / 8 | 46 | 49 | 54 | 12.8 | 21 | 19 | 21 |

| SC 12 - 04 | 12 | PT 1 / 2 | 50 | 56 | 61.5 | 15.5 | 21 | 24 | 21 |

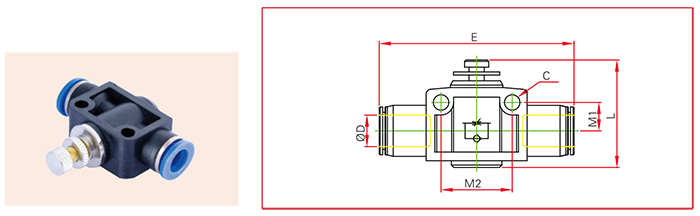

SCF Straight

| Model | Ø D | L MIN |

L MAX |

E | M 1 | M 2 | Ø P | B | C |

|---|---|---|---|---|---|---|---|---|---|

| SCF 04 | 4 | 27 | 29.5 | 40 | 6.5 | 14 | 11 | 14 | 3.2 |

| SCF 06 | 6 | 39 | 44.5 | 47 | 8.5 | 20 | 13 | 14 | 4.2 |

| SCF 08 | 8 | 42.5 | 47.5 | 52 | 9.5 | 22 | 15 | 17 | 4.2 |

| SCF 10 | 10 | 46.5 | 52.5 | 63.5 | 11 | 26 | 16 | 21 | 4.2 |

| SCF 12 | 12 | 54 | 59 | 74 | 14 | 32 | 21 | 21 | 4.2 |

Inch Series

Outlet adjustment ( blue pressure ring ), the intake adjustment ( red compression ring )

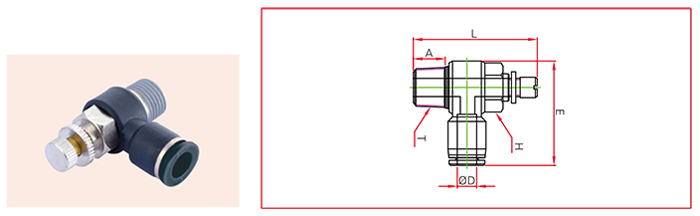

SC curved activity rotary

| Model | Ø D | T ( Thread ) |

L MIN |

L MAX |

E | A | B | Ø P | H |

|---|---|---|---|---|---|---|---|---|---|

| SC 1 / 8 - UNF | 1 / 8 | UNF 10 / 32 | 29.5 | 33 | 25 | 3.5 | 14 | 11 | 5 / 16 |

| SC 5 / 32 - UNF | 5 / 32 | UNF 10 / 32 | 29.5 | 33 | 25 | 3.5 | 14 | 11 | 5 / 16 |

| SC 5 / 32 - N 01 | 5 / 32 | NPT 1 / 8 | 36 | 41 | 29.5 | 7.5 | 14 | 11 | 7 / 16 |

| SC 5 / 32 - N 02 | 5 / 32 | NPT 1 / 4 | 43 | 48.5 | 33.5 | 11.4 | 14 | 13 | 9 / 16 |

| SC 3 / 16 - UNF | 3 / 16 | UNF 10 / 32 | 29.5 | 33 | 25 | 3.5 | 14 | 11 | 5 / 16 |

| SC 3 / 16 - N 01 | 3 / 16 | NPT 1 / 8 | 36 | 41 | 29.5 | 7.5 | 14 | 13 | 7 / 16 |

| SC 3 / 16 - N 02 | 3 / 16 | NPT 1 / 4 | 43 | 48.5 | 34 | 11.4 | 14 | 13 | 9 / 16 |

| SC 3 / 16 - N 03 | 3 / 16 | NPT 3 / 8 | 48.5 | 54 | 39.5 | 12.8 | 14 | 13 | 3 / 4 |

| SC 1 / 4 - UNF | 1 / 4 | UNF 10 / 32 | 29.5 | 33 | 26.5 | 3.5 | 14 | 13 | 5 / 16 |

| SC 1 / 4 - N 01 | 1 / 4 | NPT 1 / 8 | 36 | 41 | 29.5 | 7.5 | 14 | 13 | 7 / 16 |

| SC 1 / 4 - N 02 | 1 / 4 | NPT 1 / 4 | 43 | 48.5 | 33.5 | 11.4 | 14 | 13 | 9 / 16 |

| SC 1 / 4 - N 03 | 1 / 4 | NPT 3 / 8 | 48.5 | 54 | 39.5 | 12.8 | 14 | 13 | 3 / 4 |

| SC 5 / 16 - N 01 | 5 / 16 | NPT 1 / 8 | 36 | 41 | 32.5 | 7.5 | 17 | 14.5 | 7 / 16 |

| SC 5 / 16 - N 02 | 5 / 16 | NPT 1 / 4 | 43 | 48.5 | 37.5 | 11.4 | 17 | 14.5 | 9 / 16 |

| SC 5 / 16 - N 03 | 5 / 16 | NPT 3 / 8 | 48.5 | 54 | 40 | 12.8 | 17 | 14.5 | 3 / 4 |

| SC 5 / 16 - N 04 | 5 / 16 | NPT 1 / 2 | 56 | 61.5 | 46 | 15.5 | 17 | 14.5 | 15 / 16 |

| SC 3 / 8 - N 01 | 3 / 8 | NPT 1 / 8 | 36 | 41 | 37 | 7.5 | 21 | 18.5 | 7 / 16 |

| SC 3 / 8 - N 02 | 3 / 8 | NPT 1 / 4 | 43 | 48.5 | 41 | 11.4 | 21 | 18.5 | 9 / 16 |

| SC 3 / 8 - N 03 | 3 / 8 | NPT 3 / 8 | 48.5 | 54 | 44 | 12.8 | 21 | 18.5 | 3 / 4 |

| SC 3 / 8 - N 04 | 3 / 8 | NPT 1 / 2 | 56 | 61.5 | 49 | 15.5 | 21 | 18.5 | 15 / 16 |

| SC 1 / 2 - N 02 | 1 / 2 | NPT 1 / 4 | 43 | 48.5 | 42.5 | 11.4 | 21 | 21 | 9 / 16 |

| SC 1 / 2 - N 03 | 1 / 2 | NPT 3 / 8 | 48.5 | 54 | 45.5 | 12.8 | 21 | 21 | 3 / 4 |

| SC 1 / 2 - N 04 | 1 / 2 | NPT 1 / 2 | 56 | 61.5 | 50 | 15.5 | 21 | 21 | 15 / 16 |

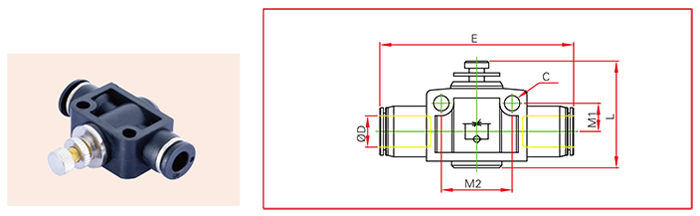

SCF Straight

| Model | Ø D | L MIN |

L MAX |

E | M 1 | M 2 | Ø P | B | C |

|---|---|---|---|---|---|---|---|---|---|

| SCF 5 / 32 | 5 / 32 | 27 | 29.5 | 40 | 6.5 | 14 | 11 | 14 | 3.2 |

| SCF 3 / 16 | 3 / 16 | 27 | 29.5 | 40 | 6.5 | 14 | 11 | 14 | 3.2 |

| SCF 1 / 4 | 1 / 4 | 39 | 44.5 | 47 | 8.5 | 20 | 13 | 14 | 4.2 |

| SCF 5 / 16 | 5 / 16 | 42.5 | 47.5 | 52 | 9.5 | 22 | 15 | 17 | 4.2 |

| SCF 3 / 8 | 3 / 8 | 46.5 | 52.5 | 63.5 | 11 | 26 | 19 | 21 | 4.2 |

| SCF 1 / 2 | 1 / 2 | 54 | 59 | 74 | 14 | 32 | 21 | 21 | 4.2 |

Metric series

Metric straight teeth, including 0-ring

PST male run tee

| Model | Ø D | T ( Thread ) |

E | L MIN |

L MAX |

A | B | H | Ø P |

|---|---|---|---|---|---|---|---|---|---|

| SC 04 - G 01 | 4 | G 1 / 8 | 29.5 | 36 | 41 | 5.5 | 15 | 12 | 10.5 |

| SC 04 - G 02 | 4 | G 1 / 4 | 33 | 43 | 50 | 6.5 | 15 | 14 | 10.5 |

| SC 06 - G 01 | 6 | G 1 / 8 | 30 | 36 | 41 | 5.5 | 15 | 12 | 13 |

| SC 06 - G 02 | 6 | G 1 / 4 | 34 | 43 | 50 | 6.5 | 15 | 14 | 13 |

| SC 06 - G 03 | 6 | G 3 / 8 | 39.5 | 49 | 55 | 6.5 | 15 | 19 | 13 |

| SC 06 - G 04 | 6 | G 1 / 2 | 46 | 53.5 | 61 | 10 | 15 | 24 | 14.5 |

| SC 08 - G 01 | 8 | G 1 / 8 | 32.5 | 36 | 41 | 5.5 | 18 | 12 | 14.5 |

| SC 08 - G 02 | 8 | G 1 / 4 | 37.5 | 43 | 50 | 6.5 | 18 | 14 | 14.5 |

| SC 08 - G 03 | 8 | G 3 / 8 | 40 | 49 | 55 | 6.5 | 18 | 19 | 14.5 |

| SC 08 - G 04 | 8 | G 1 / 2 | 46 | 53.5 | 61 | 10 | 18 | 24 | 14.5 |

| SC 10 - G 01 | 10 | G 1 / 8 | 37 | 36 | 41 | 5.5 | 22 | 12 | 18.5 |

| SC 10 - G 02 | 10 | G 1 / 4 | 41 | 43 | 50 | 6.5 | 22 | 14 | 18.5 |

| SC 10 - G 03 | 10 | G 3 / 8 | 44 | 49 | 55 | 6.5 | 22 | 19 | 18.5 |

| SC 10 - G 04 | 10 | G 1 / 2 | 49.5 | 53.5 | 61 | 10 | 22 | 24 | 18.5 |

| SC 12 - G 02 | 12 | G 1 / 4 | 42.5 | 43 | 50 | 6.5 | 22 | 14 | 21 |

| SC 12 - G 03 | 12 | G 3 / 8 | 46 | 49 | 55 | 6.5 | 22 | 19 | 21 |

| SC 12 - G 04 | 12 | G 1 / 2 | 50 | 53.5 | 61 | 10 | 22 | 24 | 21 |