DH Turbocharger

Feature

- Actuation principle: the use of high pressure source is converted into hydraulic energy of the output.

- Booster can be applied to the workpiece pushed, branding , forming , punching , riveting , cut , straightening , embossing , welding , testing , etc. Features.

- Having a hydraulic force of up properties, and does not produce heat and noise of the shortcomings , more economical and safer than hydraulic system and high efficiency.

Ordering code

| 1 Model | DHBS: Direct pressure turbocharger DHBD: Pre-pressure turbocharger |

| 2 Pressure ratio | 078: 7.8 110: 11 250: 25 |

Direct pressure turbocharger

Hydraulic cylinder output formula

A = (D) 2 x π / 4 mm 2 P2 = R x P F = A x P2 = ![]() N

N

| A | Hydraulic cylinder area ( mm 2 ) |

| D | Diameter ( mm ) |

| F | Hydraulic cylinder output ( N ) |

| P | Air pressure ( MPa ) |

| P2 | Hydraulic booster output ( MPa ) |

| R | Times higher than |

Specifications

| Model | Direct pressure | Preload type | |||||

|---|---|---|---|---|---|---|---|

| DHS - 078 | DHS - 110 | DHS - 250 | DHD - 078 | DHD - 110 | DHD - 250 | ||

| Pressure ratio | 7.8 | 11 | 25 | 7.8 | 11 | 25 | |

| The highest hydraulic ( MPa ) | 5.3 | 7.6 | 17.2 | 5.3 | 7.6 | 17.2 | |

| Discharge amount ( cc ) | 50 | 120 | 120 | 50 | 120 | 120 | |

| Operating temperature range | + 5 ~ + 60 ˚ c ( Do not freeze ) | ||||||

| Working pressure range | 2 ~ 7 kgf / cm 2 | ||||||

| Driving fluid | Filtered hydraulic oil | ||||||

| Installation | Attached tripod | ||||||

| Sensor switch | LN02A | LN03A | LN03A | LN02A | LN03A | LN03A | |

| Weight ( kg ) | 3.4 | 10.1 | 20 | 3.1 | 9.1 | 18 | |

DHS Boosters

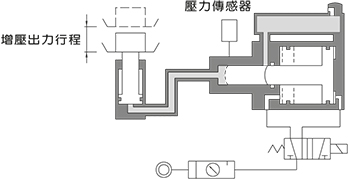

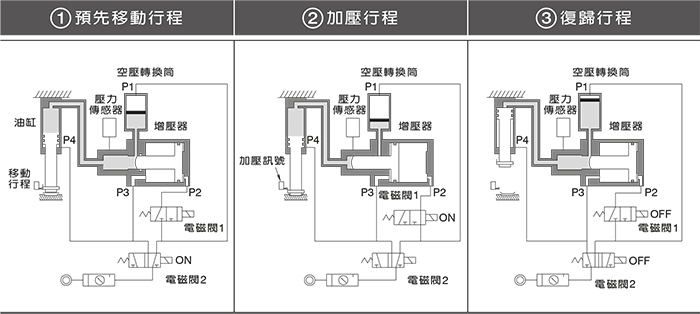

Pre-pressure turbocharger operation explanation

Turbocharger caution

Compressed air consumption ( Liters / cycle )

| Turbocharger | Use air pressure ( MPa ) | |||||

|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 04 | 0.5 | 0.6 | 0.7 | |

| DHS - 078 | 2.40 | 3.19 | 3.98 | 4.78 | 5.56 | 6.36 |

| DHD - 078 | 2.40 | 3.19 | 3.98 | 4.78 | 5.56 | 6.36 |

| DHS - 110 | 7.58 | 10.07 | 12.57 | 15.07 | 17.57 | 20.06 |

| DHD - 110 | 7.58 | 10.07 | 12.57 | 15.07 | 17.57 | 20.06 |

| DHS - 250 | 18.09 | 24.06 | 30.02 | 35.99 | 41.95 | 47.92 |

| DHD - 250 | 18.09 | 24.06 | 30.02 | 35.99 | 41.95 | 47.92 |

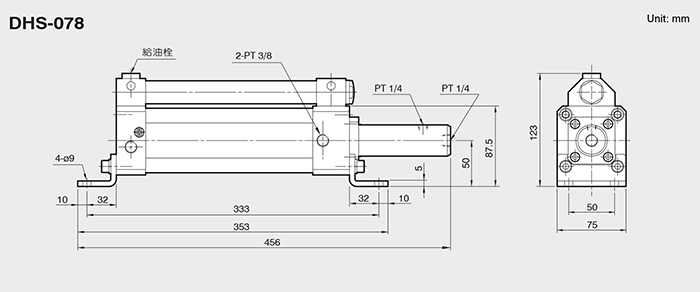

DHS Boosters

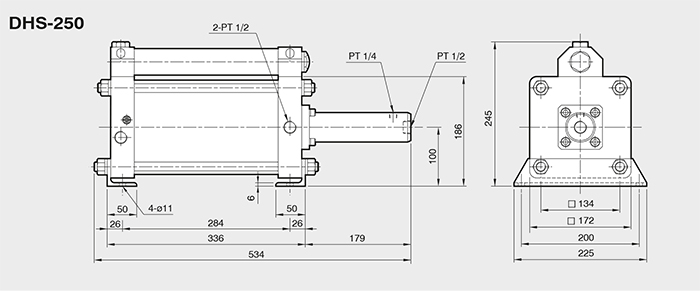

Dimensions

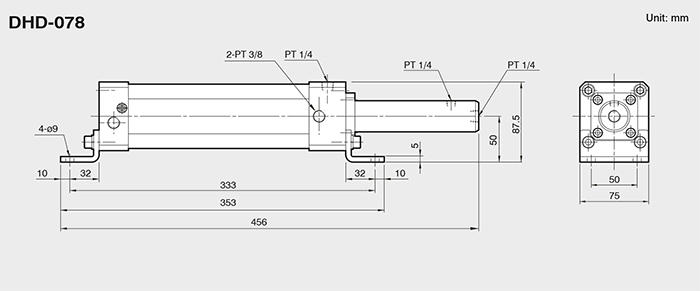

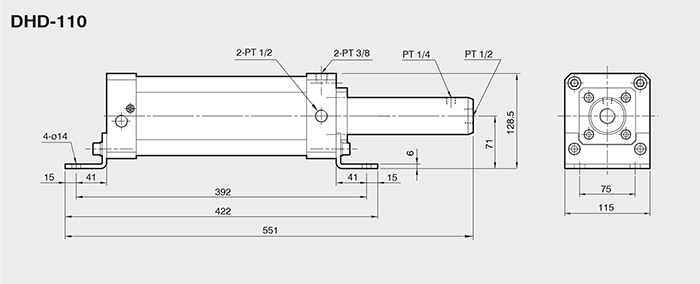

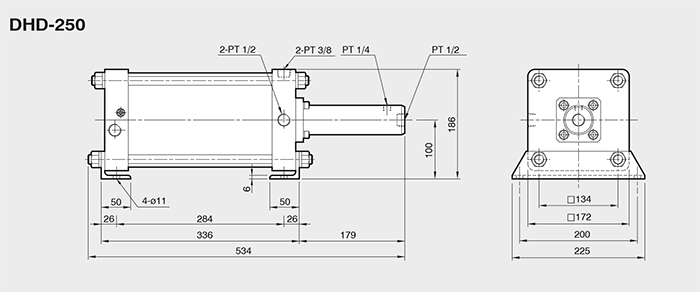

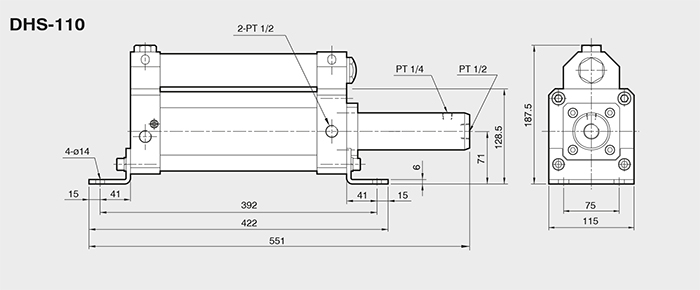

DHD Boosters

Dimensions