DP Pressurized Cylinder

Feature

- The combined turbocharger pressure cylinder and hydraulic cylinders, pneumatic source control can only use.

- Having the characteristics of oil higher power, and does not generate heat and noise of the shortcomings. More economical and safe and efficient than the hydraulic system.

Ordering code

| 1 Model | |

| 2. Thrust value | 1T 3T 5T 8T 10T |

| 3. Total travel | 50: 50 mm 75: 75 mm 100: 100 mm 150: 150 mm 200: 200 mm |

| 4. Supercharged itinerary | 5: 5 mm 10: 10 mm 15: 15 mm 20: 20 mm |

| 5. Shaft Type | None: internal tooth type Z: outer tooth type Z: outer tooth type  |

Specifications

| Model | DPD |

|---|---|

| Pressurized Thrust value | 1T, 3T, 5T, 8T, 10T |

| Stroke ( mm ) | 50, 75, 100, 150, 200 |

| Supercharged itinerary ( mm ) | 5, 10, 15, 20 |

| Working media | Filtered compressed air refueling fog |

| Working pressure range ( MPa ) | 0.3 ~ 0.8 |

| Operating temperature range ( ˚ C ) | - 10 ~ + 60 ( Do not freeze ) |

Power Cylinders' Theoretic Force Unit:N

| Type formula | 1T | 3T | 5T | 8T | 10T | ||

|---|---|---|---|---|---|---|---|

| Bore ( mm ) | ø 50 | ø 70 | ø 80 | ø 100 | ø 125 | ||

| Rod diameter ( mm ) | ø 30 | ø 40 | ø 50 | ø 60 | ø 70 | ||

Operating pressure ( MPa ) |

0.3 | A | 7216 | 18473 | 30054 | 46959 | 67630 |

| B | 377 | 778 | 919 | 1508 | 2527 | ||

| 0.4 | A | 9621 | 24630 | 40072 | 62612 | 90174 | |

| B | 503 | 1037 | 1225 | 2011 | 3369 | ||

| 0.5 | A | 12026 | 30788 | 50090 | 78265 | 112717 | |

| B | 628 | 1396 | 1532 | 2513 | 4212 | ||

| 0.6 | A | 14432 | 36945 | 60108 | 93918 | 135261 | |

| B | 754 | 1555 | 1838 | 3016 | 5054 | ||

| 0.7 | A | 16837 | 43103 | 70126 | 109571 | 157804 | |

| B | 880 | 1814 | 2144 | 3519 | 5896 | ||

| 0.8 | A | 19242 | 49260 | 80143 | 125224 | 180347 | |

| B | 1005 | 2073 | 2450 | 4021 | 6739 | ||

DP Power Cylinders

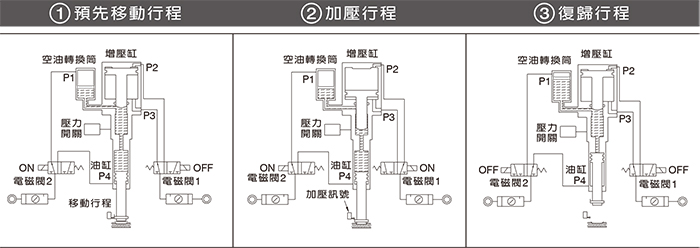

Turbocharger action description

Turbocharger caution

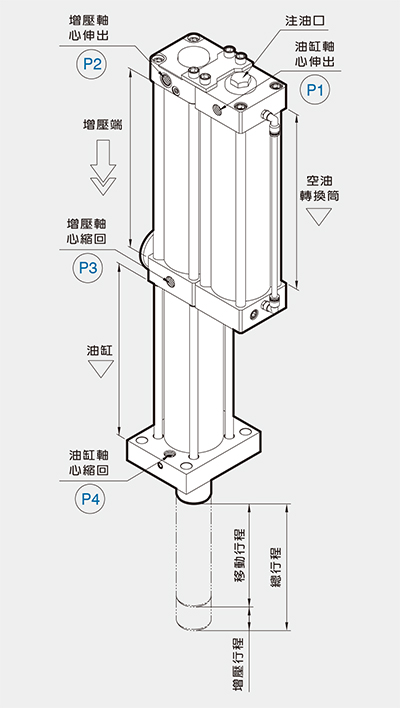

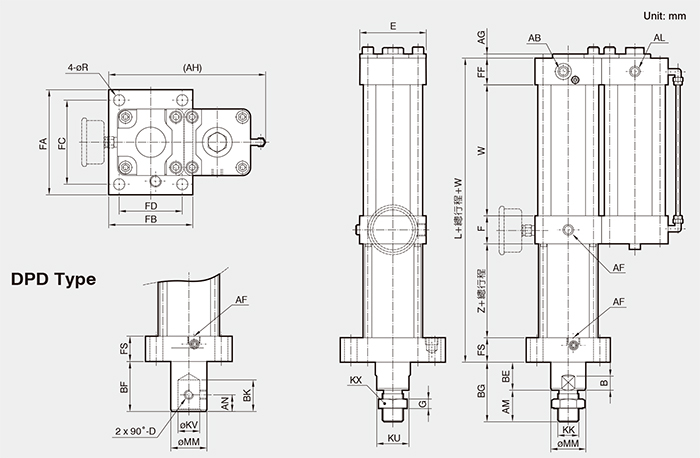

Dimensions

DPD / DPD - Z Dimensions Features / Short - stroke

Standard stroke ( Short - stroke )

| Type formula | Supercharged itinerary | |||

|---|---|---|---|---|

| 5 | 10 | 15 | 20 | |

| 1T | 50 ~ 75 | 50 ~ 125 | 50 ~ 150 | 75 ~ 200 |

| 3T | 50 | 50 ~ 100 | 75 ~ 150 | 150 ~ 200 |

| 5T | 50 ~ 75 | 50 ~ 150 | 75 ~ 200 | 150 ~ 200 |

| 8T | 50 ~ 75 | 50 ~ 150 | 75 ~ 200 | 150 ~ 200 |

| 10T | 50 | 50 ~ 125 | 50 ~ 200 | 125 ~ 200 |

| 1T - Z | 50 ~ 75 | 50 ~ 125 | 50 ~ 150 | 50 ~ 200 |

| 3T - Z | 50 | 50 ~ 100 | 75 ~ 150 | 100 ~ 200 |

| 5T - Z | 50 ~ 75 | 50 ~ 150 | 50 ~ 200 | 125 ~ 200 |

| 8T - Z | 50 ~ 75 | 50 ~ 150 | 50 ~ 200 | 100 ~ 200 |

| 10T - Z | 50 | 50 ~ 125 | 50 ~ 200 | 75 ~ 200 |

Working stroke

| Type formula | W | |||

|---|---|---|---|---|

| 5 | 10 | 15 | 20 | |

| 1T | 108 | 146 | 184 | 222 |

| 3T | 126 | 187 | 248 | 309 |

| 5T | 135 | 199 | 263 | 327 |

| 8T | 150 | 214 | 278 | 342 |

| 10T | 148 | 212 | 276 | 340 |

Dimensions

| Code / Type formula | AB | AF | AG | AH | AL | AM | AN | B | BE | BF | BG | BK | D | E | F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1T | G 3 / 8 | G 3 / 8 | 5 | 187 | G 3/ 8 | 35 | 12 | 12 | 25 | 40 | 60 | 28 | M6 x 1.0 | 75 | 40 |

| 3T | G 3 / 8 | G 3 / 8 | 6 | 227 | G 1 / 2 | 45 | 15 | 20 | 40 | 50 | 85 | 35 | M6 x 1.0 | 95 | 40 |

| 5T | G 1 / 2 | G 1 / 2 | 6 | 262 | G 1 / 2 | 60 | 20 | 20 | 40 | 60 | 100 | 40 | M10 x 1.5 | 115 | 40 |

| 8T | G 1 / 2 | G 1 / 2 | 6 | 315 | G 1 / 2 | 70 | 25 | 20 | 50 | 70 | 120 | 60 | M10 x 1.5 | 140 | 45 |

| 10T | G 3 / 4 | G 3 / 4 | 6 | 381 | G 3 / 4 | 80 | 30 | 27 | 60 | 85 | 140 | 50 | M10 x 1.5 | 174 | 55 |

| Code / Type formula | FA | FB | FC | FD | FF | FS | G | KK | KU | KV | KX | L | MM | R | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1T | 130 | 100 | 100 | 70 | 32 | 35 | 11 | M22 x 1.5 | 27 | 16 | 32 | 237 | 30 | 11 | 60 |

| 3T | 150 | 120 | 120 | 90 | 38 | 35 | 13 | M30 x 1.5 | 36 | 20 | 41 | 252 | 40 | 16 | 74 |

| 5T | 185 | 130 | 155 | 100 | 40 | 45 | 15 | M40 x 2.0 | 46 | 25 | 57 | 270 | 50 | 17 | 74 |

| 8T | 230 | 160 | 190 | 120 | 45 | 45 | 15 | M48 x 2.0 | 55 | 30 | 65 | 304 | 60 | 22 | 83 |

| 10T | 270 | 190 | 220 | 140 | 55 | 50 | 20 | M56 x 2.0 | 65 | 40 | 80 | 327 | 70 | 26 | 83 |

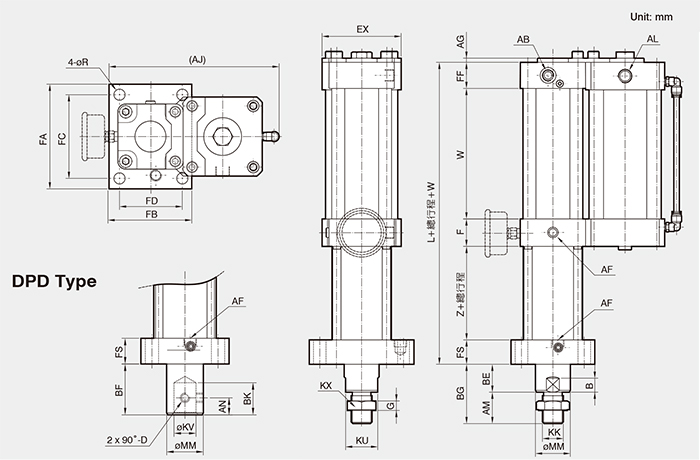

DPD / DPD - Z Dimensions Features / long - stroke

Standard stroke ( Long - stroke )

| Type formula | Supercharged itinerary | ||

|---|---|---|---|

| 5 | 10 | 15 | |

| 1T | 80 ~ 125 | 130 ~ 200 | 155 ~ 200 |

| 3T | 55 ~ 100 | 105 ~ 200 | 155 ~ 200 |

| 5T | 80 ~ 125 | 155 ~ 200 | – |

| 8T | 80 ~ 100 | 155 ~ 200 | – |

| 10T | 75 ~ 100 | 130 ~ 200 | – |

| 1T - Z | 80 ~ 125 | 130 ~ 200 | 155 ~ 200 |

| 3T - Z | 55 ~ 100 | 105 ~ 200 | 155 ~ 200 |

| 5T - Z | 80 ~ 125 | 155 ~ 200 | – |

| 8T - Z | 80 ~ 100 | 155 ~ 200 | – |

| 10T - Z | 55 ~ 100 | 130 ~ 200 | – |

Working stroke

| Type formula | W | ||

|---|---|---|---|

| 5 | 10 | 15 | |

| 1T | 108 | 146 | 184 |

| 3T | 126 | 187 | 248 |

| 5T | 135 | 199 | 263 |

| 8T | 150 | 214 | 278 |

| 10T | 148 | 212 | 276 |

Dimensions

| Code / Type formula | AB | AF | AG | AJ | AL | AM | AN | B | BE | BF | BG | BK | D | EX | F |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1T | G 3 / 8 | G 3 / 8 | 5 | 207 | G 3/ 8 | 35 | 12 | 12 | 25 | 40 | 60 | 28 | M6 x 1.0 | 95 | 40 |

| 3T | G 3 / 8 | G 3 / 8 | 6 | 247 | G 1 / 2 | 45 | 15 | 20 | 40 | 50 | 85 | 35 | M6 x 1.0 | 115 | 40 |

| 5T | G 1 / 2 | G 1 / 2 | 6 | 287 | G 1 / 2 | 60 | 20 | 20 | 40 | 60 | 100 | 40 | M10 x 1.5 | 140 | 40 |

| 8T | G 1 / 2 | G 1 / 2 | 6 | 341 | G 1 / 2 | 70 | 25 | 20 | 50 | 70 | 120 | 60 | M10 x 1.5 | 174 | 45 |

| 10T | G 3 / 4 | G 3 / 4 | 6 | 411 | G 3 / 4 | 80 | 30 | 27 | 60 | 85 | 140 | 50 | M10 x 1.5 | 204 | 55 |

| Code / Type formula | FA | FB | FC | FD | FF | FS | G | KK | KU | KV | KX | L | MM | R | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1T | 130 | 100 | 100 | 70 | 32 | 35 | 11 | M22 x 1.5 | 27 | 16 | 32 | 237 | 30 | 11 | 60 |

| 3T | 150 | 120 | 120 | 90 | 38 | 35 | 13 | M30 x 1.5 | 36 | 20 | 41 | 252 | 40 | 16 | 74 |

| 5T | 185 | 130 | 155 | 100 | 40 | 45 | 15 | M40 x 2.0 | 46 | 25 | 57 | 270 | 50 | 17 | 74 |

| 8T | 230 | 160 | 190 | 120 | 45 | 45 | 15 | M48 x 2.0 | 55 | 30 | 65 | 304 | 60 | 22 | 83 |

| 10T | 270 | 190 | 220 | 140 | 55 | 50 | 20 | M56 x 2.0 | 65 | 40 | 80 | 327 | 70 | 26 | 83 |