PT5401 Pressure transmitter

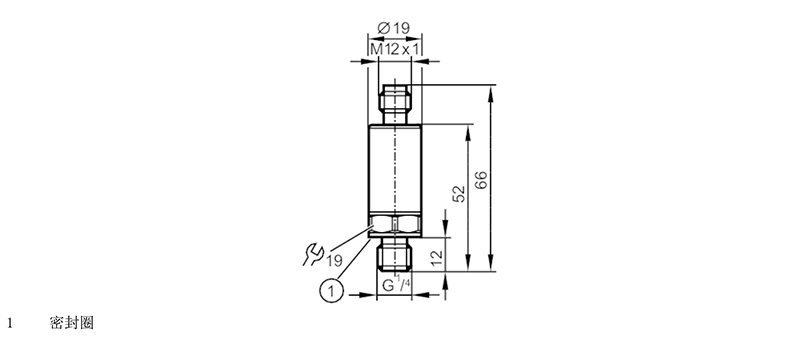

Dimensions

Specifications

| Application | ||

| Application | Used in industrial applications | |

| Medium | Liquid and gaseous media | |

| Medium temperature [ °C ] | -40 ... 90 | |

| Compressive strength [ bar ] | 625 | |

| Pay attention to compressive strength | Static | |

| Minimum burst pressure [ bar ] | 1200 | |

| Vacuum resistance [ mbar ] | -1000 | |

| Pressure | Relative pressure | |

| Electrical data | ||

| Operating Voltage [ V ] | 8.5 ... 36 DC | |

| Minimum insulation resistance [ MΩ ] | 100; ( 500 V DC ) | |

| Protection level | III | |

| Reverse protection | Yes | |

| Total input / output | ||

| Total number of inputs and outputs | Number of analog outputs: 1 | |

| Output | ||

| Number of outputs | 1 | |

| Output signal switch | Analog signal | |

| Analog output number | 1 | |

| Analog current output [ mA ] | 4 ... 20 | |

| Maximum load [ Ω ] | 720; ( Ub = 24 V; ( Ub - 8,5 V ) / 21,5 mA ) | |

| Short circuit protection | Yes | |

| Overload protection | Yes | |

| Measurement / setting range | ||

| Measuring range [ bar ] | 0 ... 250 | |

| Accuracy / deviation | ||

| Repeatability [ % of measuring range value ] | < ± 0,05; ( temperature fluctuation < 10 K ) | |

| Characteristic curve deviation [ % of measuring range value ] | < ± 0,5; ( including: drift caused by over-tightening of installation, zero point and measuring range error, non-linearity, hysteresis ) | |

| Linearity deviation [ % of measuring range value ] | < ± 0,1 ( BFSL ) / < ± 0,2 ( LS ) | |

| Hysteresis deviation [ % of measuring range value ] | < ± 0,2 | |

| Long-term stability [ % of measuring range value ] | < ± 0,1; ( every 6 months ) | |

| Temperature coefficient zero point and span [ Percentage of measurement range value ratio / 10 K ] |

< 0,1 ( -25 ... 90 °C ) / < 0,2 ( -40 ... -25 °C ) | |

| Reaction time | ||

| Step function reaction time analog output [ ms ] | 1 | |

| Working conditions | ||

| Ambient temperature [ °C ] | -40 ... 90 | |

| Storage temperature [ °C ] | -40 ... 100 | |

| Enclosure protection grade | IP 67; IP 69K | |

| Certification / testing | ||

| EMC electromagnetic compatibility | DIN EN 61000-6-2 | |

| DIN EN 61000-6-3 | ||

| Impact resistance | DIN EN 60068-2-27 | 50 g ( 11 ms ) |

| Seismic | DIN EN 60068-2-6 | 20 g ( 10...2000 Hz ) |

| MTTF [ year ] | 686 | |

| Pressure Equipment Directive | Good engineering practice; can be applied to group 2 fluids; fluids of group 1 according to demand | |

| Mechanical technical data | ||

| Weight [ g ] | 60 | |

| Material | 1.4542 ( 17-4 PH / 630 ); stainless steel ( 1.4404 / 316L ); PEI | |

| Material ( wet parts ) | 1.4542 ( 17-4 PH / 630 ) | |

| Minimum pressure cycle | 60 million; ( 1.2 times of rated pressure ) | |

| Tightening torque [ Nm ] | 25 ... 35; ( Recommended tightening torque; depends on lubrication, sealing and pressure rating ) | |

| Process connection | Threaded connection G 1/4 external thread ( DIN EN ISO 1179-2 ) | |

| Process connection seal | FKM ( conforms to DIN 3869 standard ) | |

| Integrated limiter element | No | |

| Comment | ||

| Comment | BFSL = Best Fit Straight Line | |

| LS = limit point setting | ||

| Packing unit | 1 piece | |

| Electrical connections | ||

| Connector | 1 x M12 | |