PN7571 Display pressure sensor

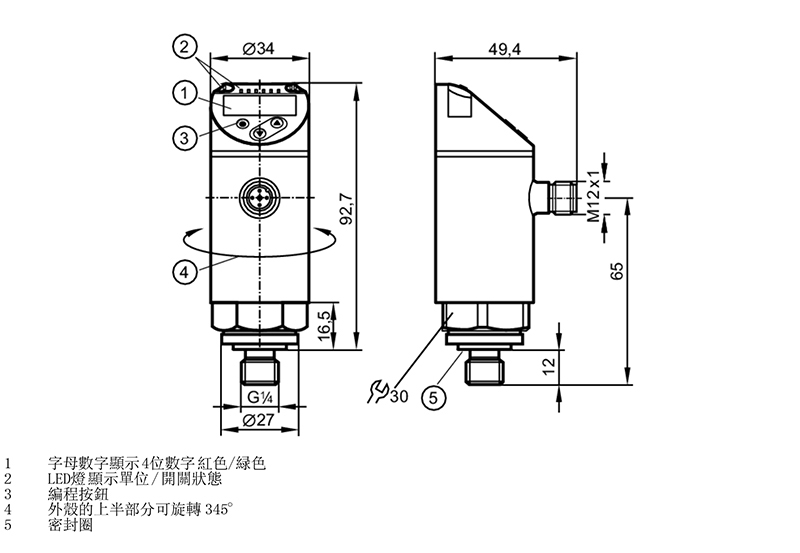

Dimensions

Specifications

| Application | |||

| Measuring element | Metal thin film battery | ||

| Application | Used in industrial applications | ||

| Medium | Liquid and gaseous media | ||

| Medium temperature [ °C ] | -25 ... 80 | ||

| Compressive strength | 500 bar | 7250 psi | 50 MPa |

| Minimum burst pressure | 1100 bar | 15950 psi | 110 MPa |

| Pressure | Relative pressure | ||

| Electrical data | |||

| Operating Voltage [ V ] | 18...30 DC; ( conforms to EN 50178 SELV/PELV standard ) | ||

| Current consumption [ mA ] | < 35 | ||

| Minimum insulation resistance [ MΩ ] | 100; ( 500 V DC ) | ||

| Protection class | III | ||

| Reverse protection | Yes | ||

| Boot delay time [ s ] | 0.3 | ||

| watchdog integrated watchdog circuit | Yes | ||

| Total input / output | |||

| Total number of inputs and outputs | Number of digital outputs: 2 | ||

| Output | |||

| Number of outputs | 2 | ||

| Output signal switch | Signal; IO-Link; ( configurable ) | ||

| Electrical design | PNP / NPN | ||

| Number of digital outputs | 2 | ||

| Output function | Normally open / normally closed; ( parameters can be set ) | ||

| Maximum switching output DC voltage drop [ V ] | 2.5 | ||

| Continuous current load of switching output DC [ mA ] | 150; ( 200 ( ...60 °C ) 250 ( ...40 °C ) ) | ||

| Switching frequency DC [ Hz ] | < 170 | ||

| Short circuit protection | Yes | ||

| Short circuit protection type | Pulse | ||

| Overload protection | Yes | ||

| Measurement / setting range | |||

| Measuring range | 0 ... 250 bar | 0 ... 3620 psi | 0 ... 25 MPa |

| Switching point, SP | 2 ... 250 bar | 40 ... 3620 psi | 0. 2 ... 25 MPa |

| Recovery point, rP | 1 ... 249 bar | 20 ... 3600 psi | 0.1 ... 24.9 MPa |

| Set step | 1 bar | 20 psi | 0.1 MPa |

| Accuracy / deviation | |||

| Switch point accuracy [ % of measuring range value ] | < ± 0,5 | ||

| Repeatability [ % of measuring range value ] | < ± 0,1; ( temperature fluctuation < 10 K ) | ||

| Characteristic curve deviation [ % of measuring range value ] | < ± 0,25 ( BFSL ) / < ± 0,5 ( LS ); ( BFSL = Best Fit Straight Line; LS = limit point setting ) |

||

| Hysteresis deviation [ % of measuring range value ] | < ± 0,25 | ||

| Long-term stability [ % of measuring range value ] | < ± 0,05; ( every 6 months ) | ||

| Temperature coefficient zero [ Percentage of measuring range value / 10 K ] |

0,2; ( -25...80 °C ) | ||

| Temperature coefficient range [ Percentage of measuring range value / 10 K ] |

0,2; ( -25...80 °C ) | ||

| Reaction time | |||

| Reaction time [ ms ] | < 3 | ||

| Programmable delay time dS, dr [ s ] | 0 ... 50 | ||

| Software / programming | |||

| Parameter setting | Hysteresis / window; normally open / normally closed; output polarity; ON delay, off delay; damping; display unit | ||

| Interface | |||

| Communication Interface | IO-Link | ||

| IO-Link | COM2 ( 38,4 kBaud ) | ||

| IO-Link revision | 1.1 | ||

| SDCI standard IEC | 61131-9 | ||

| IO-Link Device ID | 400 d / 00 01 90 h | ||

| Appearance | Smart Sensor: Process Data Variable; Device Identification, Device Diagnosis | ||

| SIO mode | Yes | ||

| Required mater port type | A | ||

| Analog process data | 1 | ||

| Two-bit output process data | 2 | ||

| Minimum processing cycle [ ms ] | 2.3 | ||

| Working conditions | |||

| Ambient temperature [ °C ] | -25 ... 80 | ||

| Storage temperature [ °C ] | -40 ... 100 | ||

| Enclosure rating | IP 65; IP 67 | ||

| Certification / testing | |||

| EMC electromagnetic compatibility | DIN EN 61000-6-2 | ||

| DIN EN 61000-6-3 | |||

| Impact resistance | DIN EN 60068-2-27 | 50 g ( 11 ms ) | |

| Seismic | DIN EN 60068-2-6 | 20 g ( 10...2000 Hz ) | |

| MTTF [ year ] | 201.44 | ||

| UL certification | UL certification number | J003 | |

| Pressure Equipment Directive | Good engineering practice; can be applied to group 2 fluids; liquids of fluid group 1 according to demand | ||

| Mechanical technical data | |||

| Weight [ g ] | 256 | ||

| Material | 1.4542 ( 17-4 PH / 630 ); stainless steel ( 1.4404 / 316L ); PBT+PC-GF30; PBT-GF20; PC | ||

| Material ( wet parts ) | 1.4542 ( 17-4 PH / 630 ) | ||

| Minimum pressure cycle | 100 million | ||

| Tightening torque [ Nm ] | 25 ... 35; ( Recommended tightening torque; depends on lubrication, sealing and pressure rating ) | ||

| Process connection | Threaded connection G 1/4 External thread Internal thread M5 | ||

| Display / operator | |||

| Display | Display unit | 3 x LED, green ( bar, psi, MPa ) | |

| Switch status | 2 x LED, yellow | ||

| Measurements | Alphanumeric display, red / green 4 digits | ||

| With scale | Yes | ||

| Comment | |||

| Packing unit | 1 piece | ||

| Electrical connections | |||

| Connector | 1 x M12; contacts Contact: gold-plated | ||